Cn70 Pneumatic Wire Collated Coil Nailer

US $ 125.00

Hits

14

Total Stock

1000 piece

feedback()

VIEW ALL

Item Details

Basic Info

- Model NO.: CN70

- Usage: Paint Spray Gun, Washing Gun, Hopper Gun, Garden Gun, Wood Packing.Wood Pallet

- Air Wrench Type: Pulse pneumatic wrench

- Brand: Kya

- Screwdriver Startup Mode: Under pressure

- Customized: Customized

- Load Capacity: 225-300PCS Nails

- Fasteners Length: 45mm-70mm

- Nails Head: 5.0mm-7.0mm

- Business Type: Manufacturer and Trading Company

- OEM Service: Available

- Transport Package: as Customer Requirement.

- Origin: China

- Type: Coil Nail Gun

- Working Style: Pneumatic

- Pneumatic Drill Range: Construction Machinery

- Degree of Automation: Semi-automatic

- Condition: New

- Weight: 3.67kgs

- Operating Pressure: 70-120psi(5-8.5kgs/Cm2)

- Shank: 2.3mm-2.9mm

- Nail Pitch: 8.0mm

- Export Markets: Global

- Trademark: KYA

- Specification: CE SGS

- HS Code: 84671900

Product Description

Cn70 Pneumatic Wire Collated Coil Nailer

Tool Specifications:

| MODEL: | CN70 (Aluminum body) |

| FIRING METHOD: | Contact trip |

| FIRING MODE: | Bump fire |

| WEIGHT: | 3.67kgs |

| DIMENSIONS: | 315 x 128 x 306mm |

| OPERATING PRESSURE: | 5-8.5kgs/cm2 (70-120psi ) |

| Customized | Customized is available if you provide a drawing or sample |

| OEM Service | Available |

Nail Specifications:

| 15° Flat wire welded coil nails | |

| LENGTH: | 45 - 70 mm |

| SHANK DIAMETER: | 2.3 - 2.9 mm |

| HEAD: | 5.0-7.0mm |

| SPACING: | 8mm |

| SHANK TYPE: | Smooth, ring & screw |

Packaging & Delivery:

| Packaging Details: | According to your requirements |

| Delivery Detail: | 7~30 days as per your quantity |

Features:

Ergonomic design, well balanced

Extra heavy-duty, die cast aluminum construction

Big load capacity

Powerful, rapid nailing performance

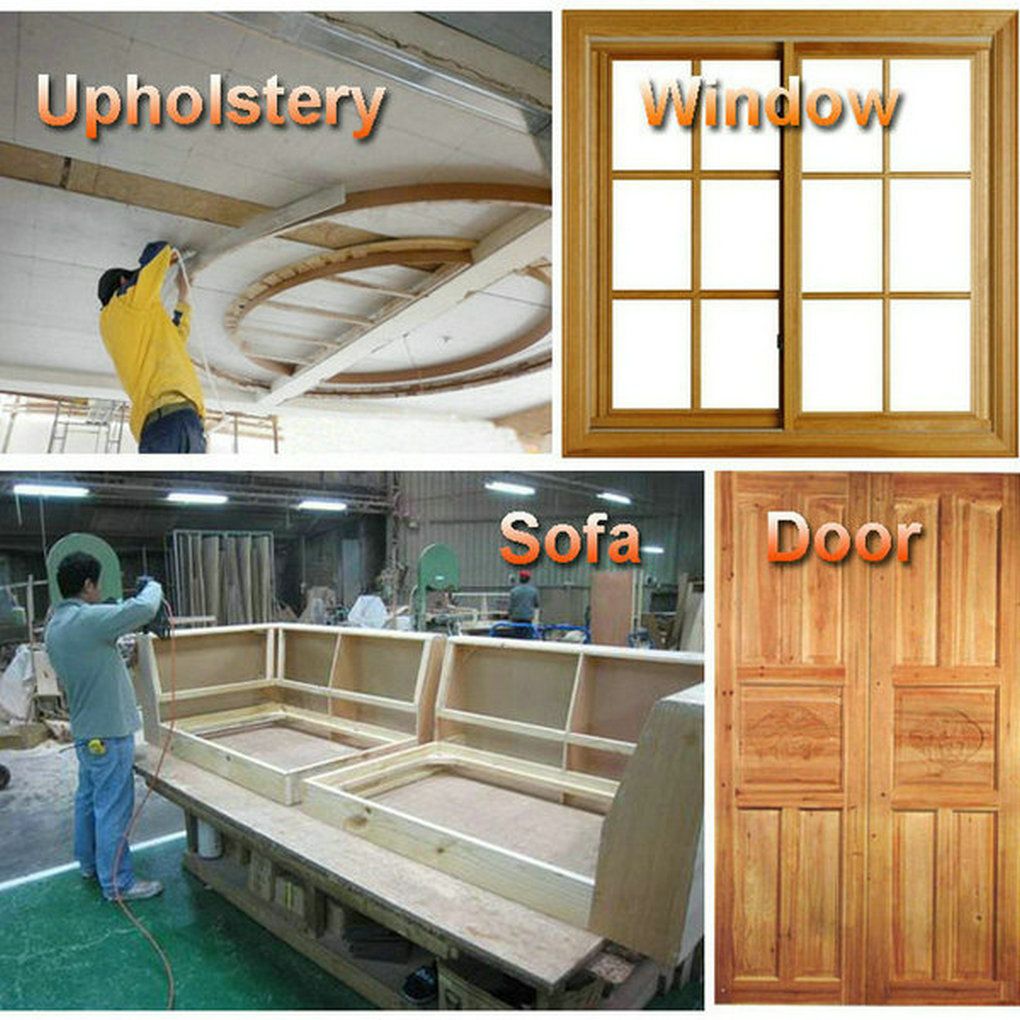

Applications:

Making and repairing pallets

Crating

Fencing

General construction applications

Service and Repars:

| No. | Symptom | Problems | Solutions | |

| 1.1 | Air Leak | Air leak in the cylinder cap when tools don't work | 1.Loose head valve piston seal or o-rings . | Check and replace the head valve piston set |

| 2.Worn or damaged o-ring or cylinder cap gasket under cylinder cap | Check and replace o-ring or cylinder cap gasket under the cylinder cap | |||

| 1.2 | Air leak in Trigger area when tools don't work | 1.Damaged o-ring in trigger valve | Check and replace o-ring | |

| 2.Damaged o-ring in trigger valve stem | Check and replace o-ring | |||

| 3.Dirt in the trigger valve | Check and clean the trigger valve | |||

| 1.3 | Air leak in cylinder cap when tools are working | 1.Damaged head valve piston o-rings | Check and replace o-rings | |

| 2.Damaged seal under cylinder cap | Check and replace seal | |||

| 1.4 | Air leak in nose when tools are working | 1.Worn or damaged bumper | Check and replace bumper | |

| 2.Loose driver(piston unit) thread | Check and replace driver(piston unit) | |||

| 1.5 | Air leak in Trigger area when tools are working | 1.Worn or damaged trigger valve head | Check and replace trigger valve head | |

| 2.Damaged head valve piston o-rings | Check and replace head valve piston o-rings | |||

| 2 | Failed to get driver(piston unit) back to the correct position completely. | 1.The driver(piston unit) is not straight or the driver guide(nose) is wrong assembled. | Straighten the driver(piston unit) or verify driver guide(nose) and magazine | |

| 2.Worn or damaged nozzle | Check and replace nozzle | |||

| 3.The space between piston o-ring and cylinder is too tight. | Check if the cylinder is adequate lubrication or replace the o-ring on the piston. | |||

| 3 | Work weakly and sluggishly | 1. Worn or damaged piston o-ring | Check and replace piston o-ring | |

| 2.Inadequate lubrication for head valve piston o-rings or too tight head valve piston o-rings | Place 2 or 6 drops of oil on o-rings or replace head valve piston o-rings | |||

| 3.Dirt in the nozzle | Check and clean the nozzle | |||

| 4 | Tool jams frequently | 1.Damaged or Worn driver (piston unit) | Check and replace driver (piston unit) | |

| 2.Damaged or Worn driver guide (nose) | Check and replace driver guide (nose) | |||

| 3.Driver guide cover is bent,so the space between driver guide cover and driver guide is too big | Check and replace driver guide cover | |||

| 5 | Nail can not be shot | 1. Driver (piston unit) can't return to the correct position. | Refer to no. 1 Symptom | |

| 2.Driver guide(nose) can not match magazine well | Check and correct the position between driver guide(nose) and magazine | |||

| 3.Worn or damaged nail pusher compression spring | Check and replace nail pusher compression spring | |||

FAQ:

1.Q:Do you have your own production factory?

A:Yes,we not only have our own factory,We also have a cooperative relationship with more than one hundred factories in China

2.Q: Can you send us samples?

A: We are pleased to send you the sample to test the quality and market.

3.Q: About your products, could you do it OEM?

A: Yes, OEM service is available.

4.Q: Do you also provide spare parts of pneumatic tools?

A: Once we confirm the models you'd like to order, we will send you the diagram for checking and also suggest you some easy-broken parts.

5.Q: For the product, could you spray other color of painting?

A: Yes, color can be customized.

6.Q: What's the delivery time?

A: It usually takes about 20-30 working days to produce one order.

7.Q: How is the payment terms?

A: Normally T/T 30% in advance and T/T 70% before shipment.

8.Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model should not be less than MOQ.

9.Q: How does your factory do regarding quality control?

A: We always pay great attention to quality control from the very beginning and every product was tested piece by piece before delivery.

10.Q: Do you have quality certification?

A: Yes, we have CE, SGS,ISO, ect.

Why choose KYA?

1.Short production time:Our company have established the strong partner-ship with over 100 factories and We have our own factory.

2.Reasonable prices and High quality:Quality and prices are our focus because we know what you will care at most.

3.Satisfactory after-sales service: Middle time production report with photos will be sent to you and also reconfirm accomplished date. We will establish close contact with you.Any problem you will get reply at the first time.

4.Free samples: Free samples available at any time.

You can get competitive prices from us because we possess big manufacturing relationship in China.

About Us:

Contact Us:

Tel: 0086-519-89886376

Fax: 0086-519-89196376

Fax: 0086-519-89196376

VIEW ALL

More products from this supplier

CHANGZHOU KYA TRADING CO., LTD.

CHANGZHOU KYA TRADING CO., LTD. Send Letter

Send Letter Online Chat

Online Chat

product options

product options