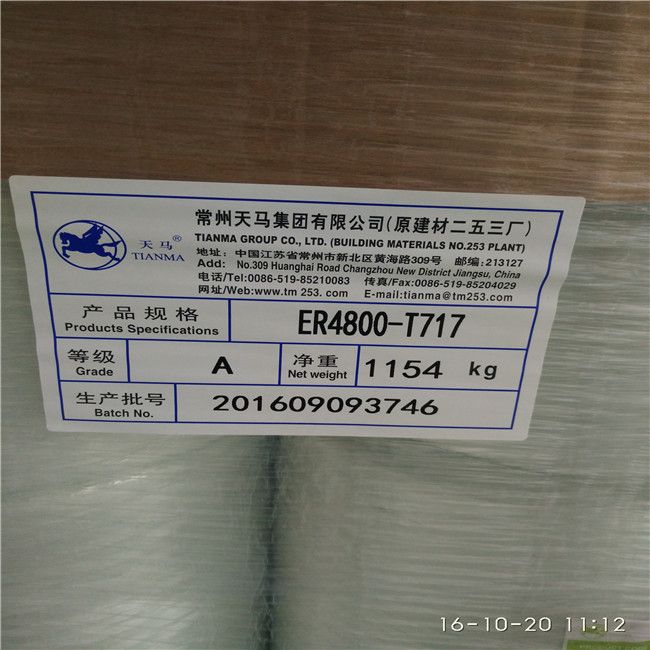

- Model NO.: EMC

- Technique: Chopped Strand Fiberglass Mat (CSM)

- Fiberglass Type: E-Glass

- CTN Size: 28*28cm

- CTN/40hq: 770

- Transport Package: Ctns

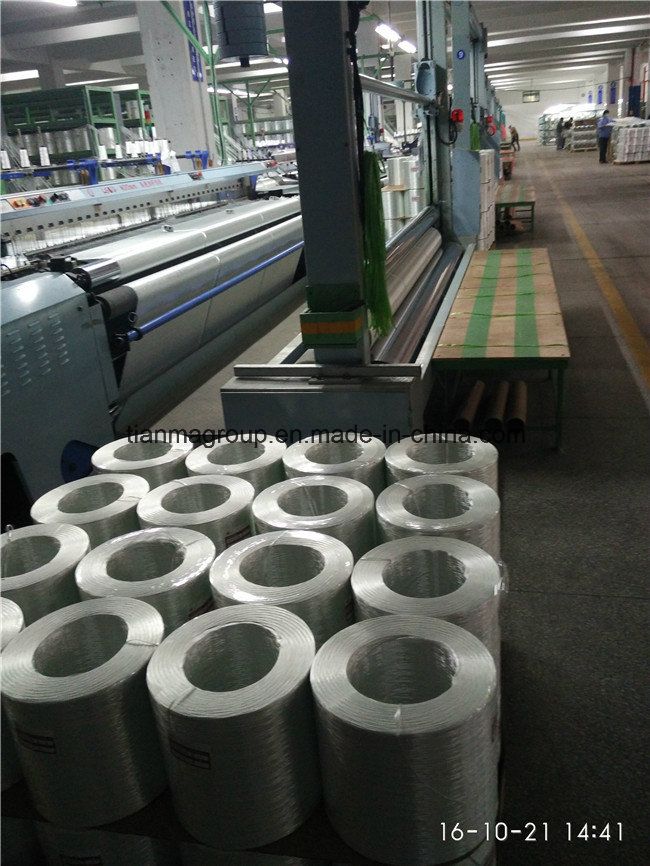

- Origin: Changzhou, China

- Certification: CE, ISO, Dnv

- Mat Type: Combination Mat

- Class: a

- Plt Size: 1120*1120mm

- Trademark: Tianma

- Specification: 30KG/CTN

- HS Code: 7019310000

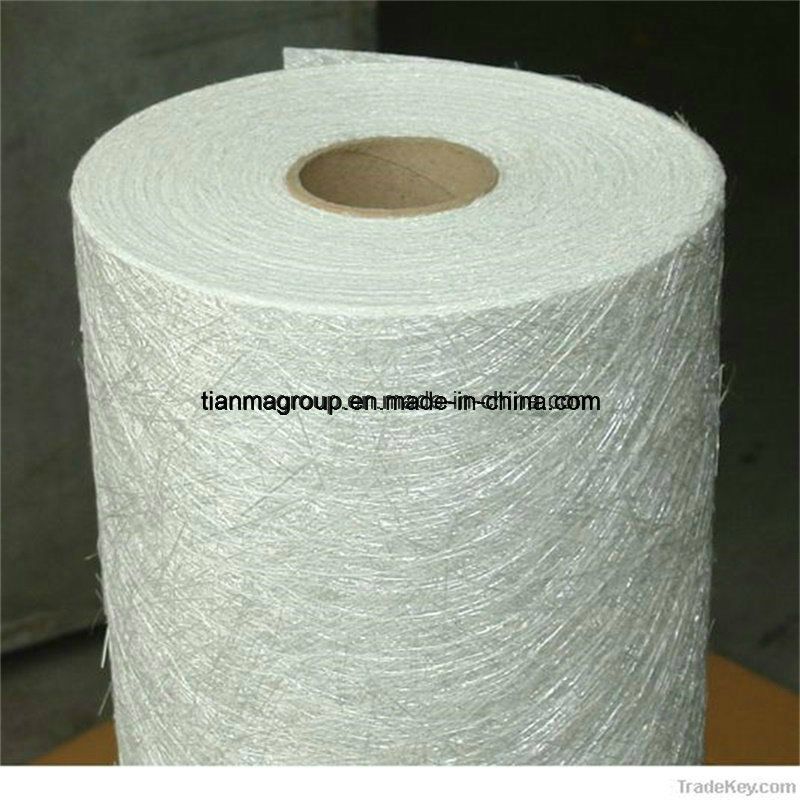

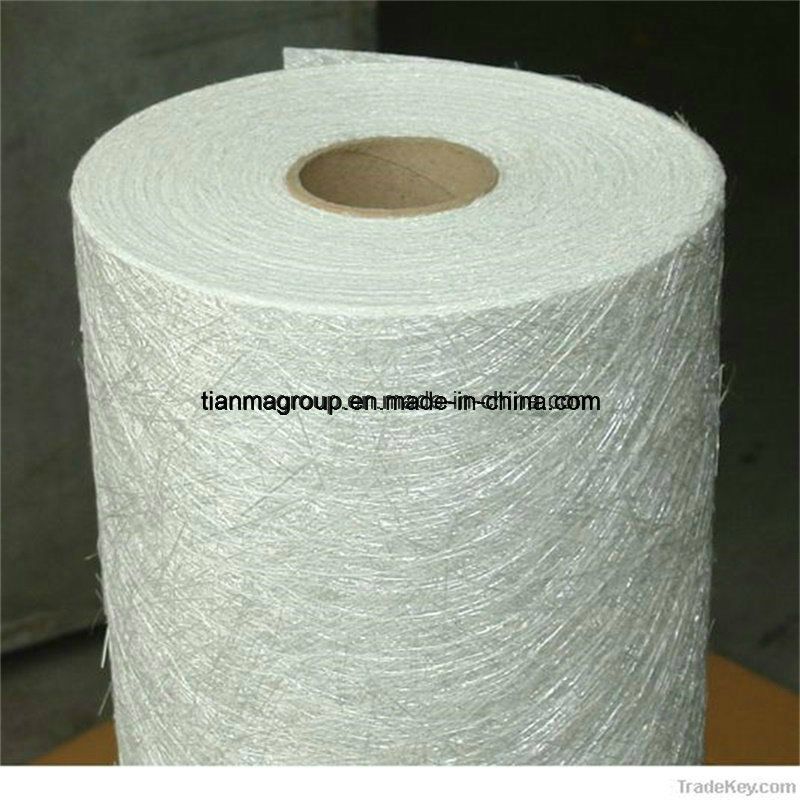

Chopped Strand Mat

Glass fiber chopped strand mat is made of randomly distributed chopped strands held together by a powder binder.Our products provide outstanding performance in a variety of hand lay-up applications to mold many types of composites with both polyester and vinylester resins for use in the transportation, recreation, marine and construction sectors.

Chopped Strand Mat (CSM) is made up of chopped strands of glass fibre laid randomly and held together with a binder or stitching. Chopped Strand Mat is designed to cover a wide range of layup techniques. It easily conforms to moulds and has fast wet out properties.

Available Fibre

Chopped Strand Mat is mainly produced in Fibreglass (E-glass) but is also available in ECR glass.

Binder Options

Chopped Stand Mat can be chemically or mechanically bound. Chemical binders include Emulsion and Powder. Both chemical binders are highly soluble and work well with different resin systems. Emulsion is suitable for use with polyester while the Powder binder is more suited to Vinyl-ester, Epoxy and corrosion resistant resins.

High tensile strength, Insuring no breakage when unwinding; Uniform fiber glass content; Superior acid corrosion resistance

High tensile strength, suitable for use in hand lay-up process to produce large-area parts; Good wet-through and fast wet-out in resins, rapid air lease; High mechanical strength; Superior acid corrosion resistance.

It is compatible with UP, VE, EP, PF resins.

The roll width ranges from 50mm to 3200mm.

Additional demands on wet-out and decomposition time may be available upon request.

DATA SHEET| Specifications | Weight G/M2 | Break Strength ≥N/25mm | Package Weight kg | Binder content % |

| EMC-250-3200 | 250 | 40 | 30 | 1.8-8.5 |

| EMC-300-3200 | 300 | 60 | 30 | 1.8-8.5 |

| EMC-450-3200 | 450 | 60 | 30 | 1.8-8.5 |

| EMC-600-3200 | 600 | 80 | 30 | 1.8-8.5 |

| Key Features: | Our Range: | |

|---|---|---|

| Suitable for use in complicated mould shapes | Weights: | 225 G/M² - 600 G/M² |

| Quicker and easier lay-up reducing labour | Widths: | Widths: 50mm - 3300mm |

| Very fast wet out capability reducing fill time | ||

| Increased control of finished part thickness | ||

| Able to withstand high RTM pressures | ||

| Lower resin requirement to fill larger moulds | ||

| Available in a variety of weight combinations and widths |